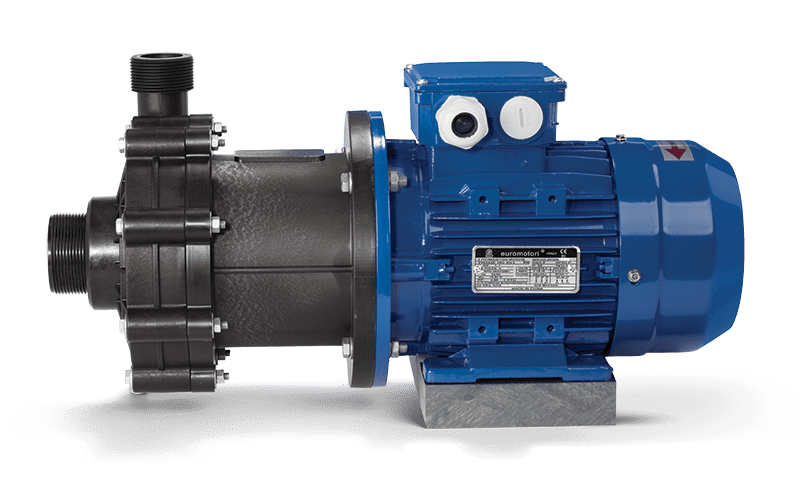

plastic MAG-DRIVE PUMPS

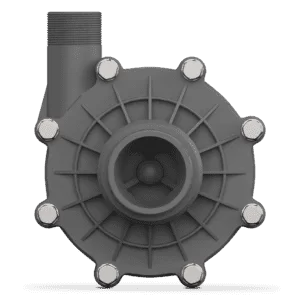

Magnetically driven thermoplastic pumps. Leak-free chemical pumps manufactured from corrosion proof plastic with no metal parts in direct contact with aggressive liquids: all fluid contact parts are made of Polypropylene (PP) or Polyvinylidene Fluoride (PVDF), which are chemically resistant materials.

Neodymium-Iron-Boron magnets

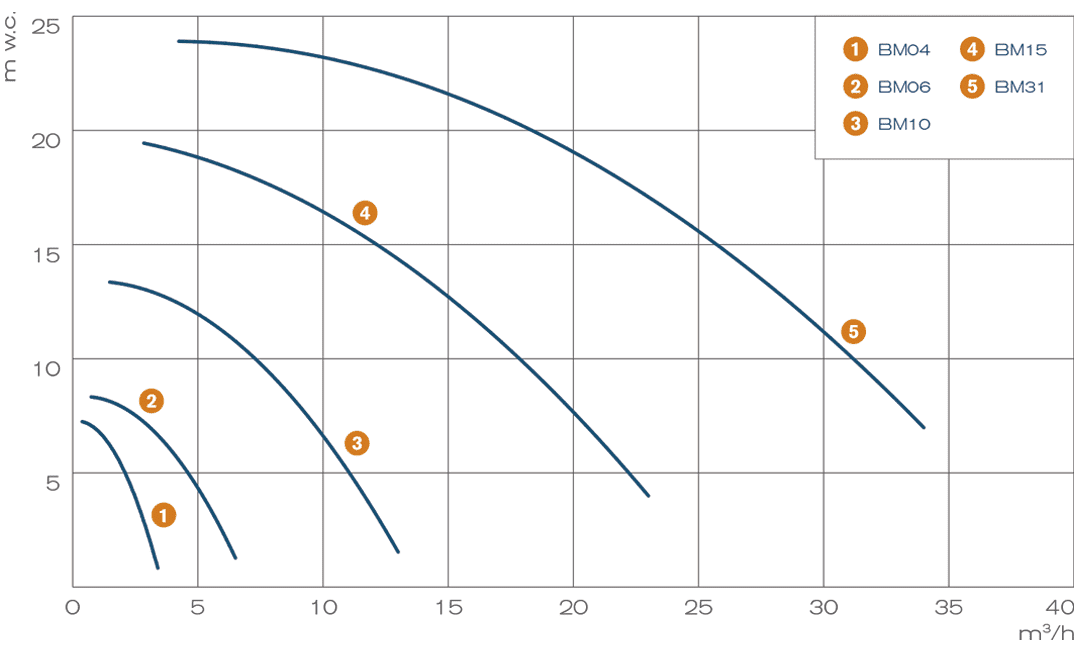

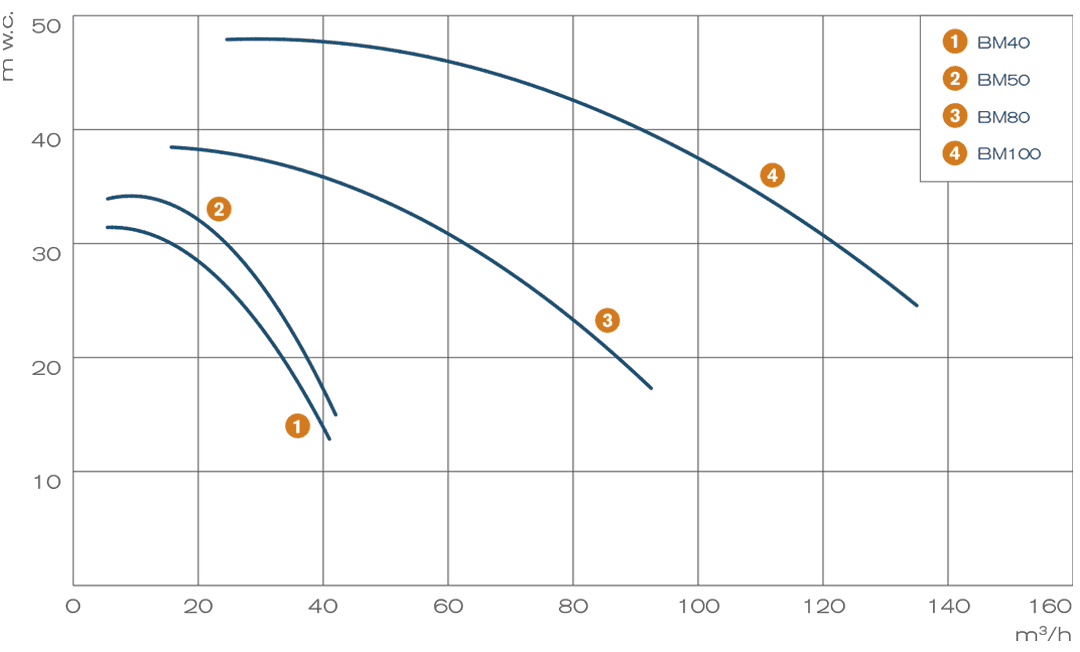

MAX FLOW-RATE: 135 m³/h

MAX HEAD: 48 mwc

threaded connections (standard) OR FLANGES (OPTIONAL)

SPECIAL MODELS FOR PER explosive atmosphere (ATEX ZONE 2)

PLASTIC MATERIAL: PP, PVDF

Neodymium-Iron-Boron magnets

MAX FLOW-RATE: 135 m³/h

MAX HEAD: 48 mwc

threaded connections (standard) OR FLANGES (OPTIONAL)

SPECIAL MODELS FOR PER explosive atmosphere (ATEX ZONE 2)

SERIEs MD

MODEL MD06 → MD70

PP

(POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of corrosion-free pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

PVDF

(POLYVINYLDENFLUORIDE)

Fluorinated thermoplastic with excellent resistance to corrosion and temperature. PVDF covers a wide range of applications but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C